848 Brickell Ave. P-5, Miami, FL 33131

848 Brickell Ave. P-5, Miami, FL 33131 BidRoom@StoneSheets.com

BidRoom@StoneSheets.com +1 954 840 6888

+1 954 840 6888

Lightweight Stone Panels

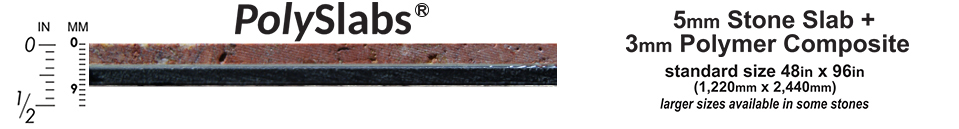

PolySlabs® is our thin, non-structural panel with polymer composite backing with to support softer stones such as marbles, travertines, and limestones, not available in SlimSlabs®. PolySlabs® materials are used in applications such as shower and tub surrounds, furniture, casework, simple cladding applications such as planters and signs, and other applications with a substrate for support. Multiple textures and patterns available, according to the stone selected, to make the most complicated designs simple and easy to install. Ask about our solid stone accessories to complete your new construction or remodeling projects.

INSTALLATION

PolySlabs® lightweight stone panels are installed using mastic, structural silicone, and other adhesives, similar to large format tiles, or epoxy in some situations such as signs and planters; setting pins or double sided tapes can be used during curing. PolySlabs® is a non-structural material that should be used only to dress and clad structurally sound applications that comply with an engineered deflection rating of L/300.

When using silicone for edge sealing of PolySlabs®, it is important to use materials that are non-staining and comply with the stone selected.

Quality Assured

Design assistance and stone consulting is available to ensure projects full potential is maximized and budgets are satisfied.

Precision manufacturing ensures even the most complicated designs are completed using the best equipment and stringent guidelines.

Stone is selected by hand, ensuring quality standards are met or exceeded.

Quality Control Standards are checked in triplicate, during rough production, final production, and at shipping.