848 Brickell Ave. P-5, Miami, FL 33131

848 Brickell Ave. P-5, Miami, FL 33131 BidRoom@StoneSheets.com

BidRoom@StoneSheets.com +1 954 840 6888

+1 954 840 6888

Rainscreens, Facades, & Curtainwalls

This Midtown Manhattan project demanded a custom, natural looking texture on the deepest black granite available for the facade, balcony caps, and 2" thick solid stone base. These blocks were custom selected from India, and used for all the materials. We fabricated bonded corners throughout to create sharp edges and corners at the building and adjacent materials at curtainwall areas.

This New York glass and stone panel facade required a specific stone match to a 1902 stone on the adjacent building, covered in natural patina. After custom selecting from over 22 unique quarry swatches, the match required special extraction from a Portugal quarry, and due to rushes in the project, all production was completed in under 12 weeks. Ask your StoneSheets Representative to help match existing stones!

This simple project in appearance is actually quite advanced. The Veteran's Memorial project was coordinated with a variety of engineers, including NASA, to time perfectly with the sun's rays. On November 11th, at 11:11am, sun shines directly through openings in the columns, which are dedicated to each military branch, to light up the Great Seal of the United States mosaic. A wonderful dedication to our Veterans and Armed Forces.

This facade on Miracle Mile has 3/8" thick grooves placed at 1" intervals, balancing through the panels to coordinate with the joints so the horizontal striations look continuous around the building. Precision manufacturing and careful attention to panel design was required to complete this facade. Under the panels is a Continuous Insulation Curtainwall using Dow® Thermax insulation for superior thermal protection.

This Indian grey granite was custom quarry extracted and contains our proprietary ballistic material within the TL panels on the lower portion of the facade. The column covers were custom carved in circular fashion to coordinate perfectly with the curtainwall panels. Bonded Corners were featured on the lower edges of facade to conceal surveillance equipment and complete exposed edges of the soffit panels.

Custom limestone, extracted for its consistency in color, and solid stone caps were required, along with bonded corners on the lower row of the curtainwall. This facade involved many different designers and architects from various parts of the world, requiring careful coordination and execution. The top edges were finished with 2" thick solid caps, in the same block selection as the facade panels.

Creme Bianco Limestone TL-20 panels with bonded corners at adjacent curtainwall were made with close coordination of foreign curtainwall designers and contractors. This project, like many, were delivered in phases, with color coding used to bridge language barriers of installation crews, including detailed packing and labeling of the panels, and coordinated details for installation maps.

Bonded corners around the building and at openings made installation quick and easy. Foreign designers and curtainwall designers, graduates of CWCT (Centre for Window and Cladding Technology), participated in the design and supervision of the facade. Close involvement was required in this foreign project, and foreign time meetings, with the facade required to be tested through multiple governing agencies.

Indian grey granite was extracted for the entire project, though installation was in phased spread out over a year long period. Storage of blocks was not an issue, as phases were not planned well in advance, and advanced lamination of all panels was required. When projects require tiered installation times, preserving the same lot of blocks is important for the color of the facade to be continuous after installation.

This facade renovation was applied over existing exterior to reface the building with Bianco limestone. The curtainwall was completed in just 4 weeks, using existing inventory blocks, and panels were coated in a premium Akemi® hydrophobic sealer to protect the bright white stone finish.

Custom green slate panels required bonded corners and radius edges at the soffit; coordinating tile was created from the same block for adhesive bonding at the lower sidewalk level of the project. Bonded returns made easy work of clean lines and simple, clean onsite installation.

This project featured the Thermax® insulation system by Dow Building Solutions, to which panels were modified to attach to a curtainwall system that did not penetrate the thermal barrier of the rigid insulation system.

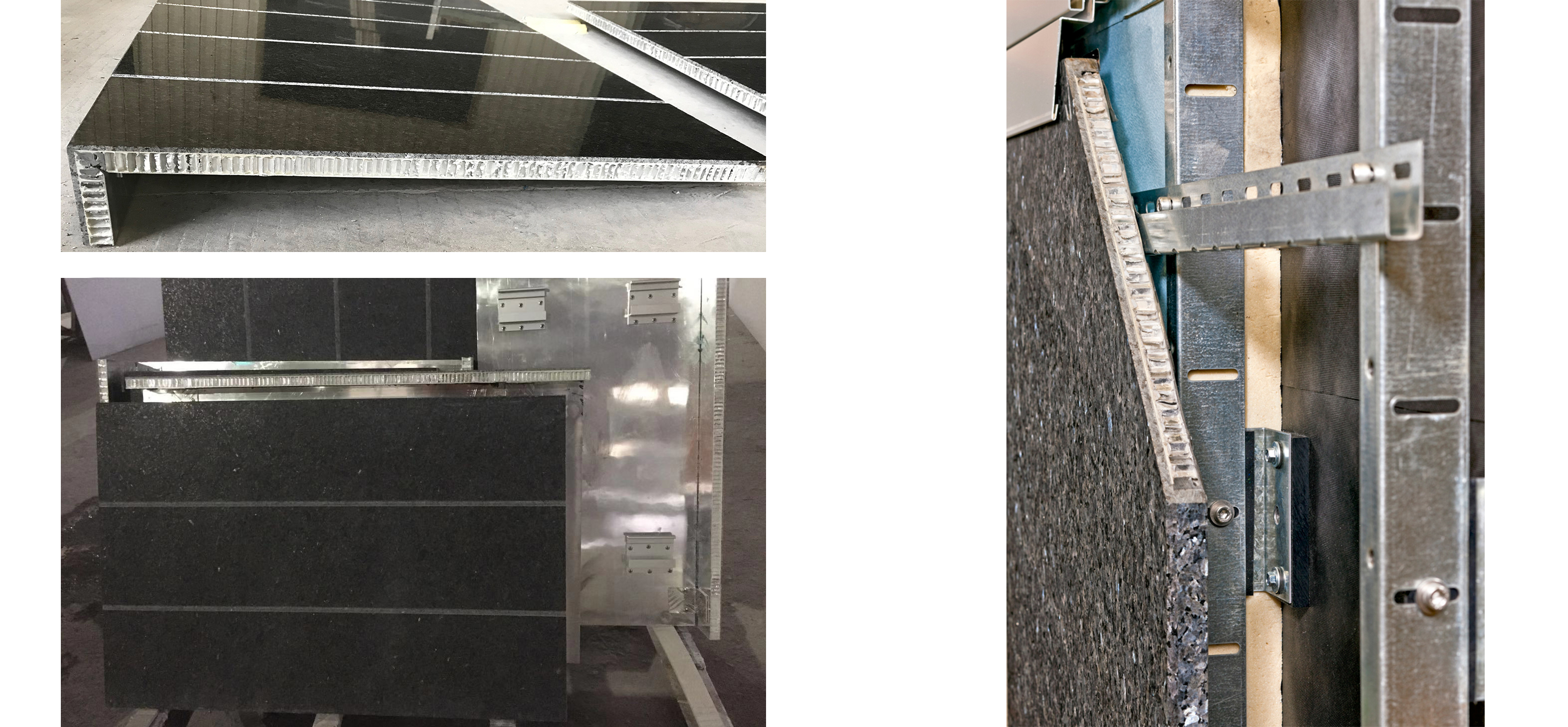

Using our typical anchors, the panelized facade featured Absolute Black granite with a continuous groove pattern. Organized installation maps and design details allow for easy installation and less jobsite hours.

Pure white marble interior facade, coordinating with a glazed spider attachment curtainwall ceiling. Pure white characteristics required special selection of blocks to achieve this pure white look.